IMPAX/SK Process Monitoring Systems

Impax Process Monitoring

Visual process monitors use enhanced envelope-based monitoring of force signals to visually display full process detail, allowing easy setups and enforcing quality standards.

Unit of Measure

| Items |

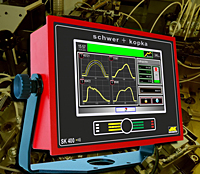

/Asset/400-2.jpg /Asset/400-2.jpg SK 400 SK 400 Process Monitoring System |

/Asset/400-2.jpg /Asset/400-2.jpg SK 400 lean SK 400 lean Process Monitoring System |

/Asset/sk500-800.jpg /Asset/sk500-800.jpg SK500 SK500 Process Monitoring System |

/Asset/sk500-800.jpg /Asset/sk500-800.jpg SK 800 SK 800 Process Monitoring System |

/Asset/sk400-z.jpg /Asset/sk400-z.jpg SK 400Z SK 400Z Process Monitoring System |

|||||

| Width | N/A | |||||||||

| Width without Yoke | N/A 230 mm | N/A 230 mm | N/A 290 mm | N/A 398 mm | N/A 230 mm | |||||

| Height | N/A | |||||||||

| Height without Yoke | N/A 165 mm | N/A 165 mm | N/A 240 mm | N/A 331 mm | N/A 165 mm | |||||

| Depth | N/A | |||||||||

| Depth without Yoke | N/A 60 mm | N/A 60 mm | N/A 115 mm | N/A 135 mm | N/A 60 mm | |||||

| Data Ports | N/A Ethernet serial RS-232 Teleservice USB | N/A Ethernet serial RS-232 Teleservice USB | N/A 2xUSB Ethernet serial RS-232 Teleservice Teleservice | N/A 2xUSB Ethernet serial RS-232 Teleservice Teleservice | N/A Ethernet serial RS-232 Teleservice USB | |||||

| Modular Software | N/A Y | |||||||||

| On Board PC | N/A N | N/A N | N/A Y | N/A Y | N/A N | |||||

| Digital Inputs | N/A 5 | |||||||||

| Digital Output | N/A 5 | |||||||||

| Sensor Inputs | N/A Up to 16 | N/A Up to 2 | N/A Up to 16 | N/A Up to 16 | N/A Up to 16 | |||||

| Monitor | N/A 7 inch (in) TFT color touch-screen with high resolution | N/A 7 inch (in) TFT color touch-screen with high resolution | N/A 10.4 inch (in) TFT color touch-screen | N/A 15 inch (in) TFT color touch screen | N/A 7 inch (in) TFT color touch-screen with high resolution | |||||

| DC Supply Voltage | N/A 24 V | |||||||||

| Supply Power | N/A 30 W | N/A 30 W | N/A 60 W | N/A 60 W | N/A 30 W | |||||

| Weight | N/A 3.0 kg | N/A 3.0 kg | N/A 7 kg12 kg | N/A 7 kg12 kg | N/A 3.0 kg | |||||

| Mounting Options | N/A Floor pedestal Panel mount Swivel Yoke | |||||||||

| Monitoring Functions | N/A Absolute force measurement Analyzes process stability and monitoring quality DMI Die Match Indicator for thread rollers Mandon® reporting system Mandonic auto enveloping system New intelligent auto start feature after machine stop Part data memory (Set-up recall) Press set-up assistance SKPuzzlemaster expert monitoring programs for special types of errors and forming operations Tool protection Trending stop/go chart | N/A Absolute stroke position display Auto start feature after machine stop Envelope monitoring of forming force signals (up to 2 channels) Peak Force Readout Q-factor with stop logic RPM display SKAutomaster-Autoset feature SKPartmaster-set-up assistance upgrade (Optional) SKQmaster- wave form stabilizer feature for older machines SKSinglemaster-prevents idle strokes from biasing learned values Supervisory Control Lockout | N/A Absolute force measurement Analyzes process stability and monitoring quality Continuously evaluates process stability and monitoring quality DMA or DMI-die set up assistant (Die Match - Automatic or Manual) for thread rollers Machine loading profile Machine performance and error memory Mandon® reporting system Mandon®-Technology Mandonic auto enveloping system M-Apps machine analysis New intelligent auto start feature after machine stop Part data memory Press set-up assistance SKPuzzlemaster monitoring programs for specific error detection Tool protection Trending stop/go chart | N/A Absolute force measurement Analyzes process stability and monitoring quality Continuously evaluates process stability and monitoring quality DMA or DMI-die set up assistant (Die Match - Automatic or Manual) for thread rollers Machine loading profile Machine performance and error memory Mandon® reporting system Mandon®-Technology Mandonic auto enveloping system M-Apps machine analysis New intelligent auto start feature after machine stop Part data memory Press set-up assistance SKPuzzlemaster monitoring programs for specific error detection Tool protection Trending stop/go chart | N/A Intelligent re-start function after machine stops Mandon® reporting system Mandonic auto enveloping Part data memory Separate limits for collision, breakage, trend and idling TL filter function to eliminate unwanted stops caused by chip build up. Trending stop/go chart Variomaster function ensures proper monitoring of all stations when machine is emptying | |||||

| Technical Features | N/A EMR-proof, ergonomically designed flat enclosure Machine data collection networkable for machine data collection Part counters for job size, tool life, Unattended production runs with Eco-Stop and SPC intervals SKTelemasfer for teleservice Sorting and batching logics | N/A EMR-proof, ergonomically designed flat enclosure, Part counters for job size and tool life. Ready for collection of production data via IMPAX TSS System SKTelemaster for remote diagnosis Sorting and batching logic Speed Disconnect System | N/A Data networking option EMR-proof, ergonomically designed flat enclosure, Fanless PC with Windows XP- Embedded and CF-Memory Part counters for job size, tool life, Unattended production runs with Eco-Stop and SPC intervals SKTelemaster for remote service Sorting and batching logic | N/A Data networking option EMR-proof, ergonomically designed flat enclosure, Fanless PC with Windows XP- Embedded and CF-Memory Part counters for job size, tool life, Unattended production runs with Eco-Stop and SPC intervals SKTelemaster for remote service Sorting and batching logic | N/A EMR-proof, ergonomically designed flat enclosure, Outputs for machine data collection Part counters for job size, tool life, Unattended production runs with Eco-Stop and SPC intervals SKTelemasfer for teleservice Sorting and batching logic | |||||

| Technical Data | N/A Crank angle decoder option Data back-up (network or USB) High output digital signal amps Powerful digital signal analysis processor RFID controlled user access | N/A Crank angle encoder option Data back-up (network or USB) High output digital signal amps Multi-color warning light (opt.) Powerful digital signal analysis processor RFID controlled user access | N/A Crank angle decoder option Data back-up (network or USB) High output digital signal amps Powerful digital signal analysis processor | N/A Crank angle decoder option Data back-up (network or USB) High output digital signal amps Powerful digital signal analysis processor RFID controlled (SK 800 only) | N/A Crank angle encoder option Data back-up (network or USB) High output digital signal amps Multi-color warning light (opt.) Powerful digital signal analysis processor RFID controlled user access | |||||

| Features | N/A BDE Outputs including cycle and good part pulses Cockpit Dashboard with multifunction displays Digital In/Out Logic DSP Based System Mandon Technology- Suggests operational improvement to the operator Mandonic automatic enveloping system Multiple Counters Optional features for specific user needs Press Frame Monitoring Production Monitoring Option RFID User Access Simple to Operate | N/A Compact enclosure Data networking option Mandonic automatic enveloping system Multifunction Display Multiple Counters Protection against collision Simple to Operate Tool breakage monitoring Trend monitoring for wear User access controlled by RFID key | N/A BDE Outputs including cycle and good part pulses Cockpit Dashboard with multifunction displays Digital In/Out Logic Foxmatic Monitoring: New technique to monitor within the envelopes. Mandon Technology - Suggests operational improvements to the operator Mandonic Auto-Enveloping M-Apps - Machine Productivity Analysis Multiple Counters Optional feature for specific user needs PC-Based System Press Frame Monitoring Production Monitoring Option RFID User Access Simple to Operate | N/A BDE Outputs including cycle and good part pulses Cockpit Dashboard with multifunction displays Digital In/Out Logic Foxmatic Monitoring: New technique to monitor within the envelopes. Mandon Technology - Suggests operational improvements to the operator Mandonic Auto-Enveloping M-Apps - Machine Productivity Analysis Multiple Counters Optional feature for specific user needs PC-Based System Press Frame Monitoring Production Monitoring Option RFID User Access Simple to Operate | N/A Compact enclosure Data networking option Mandonic automatic enveloping system Multifunction Display Multiple Counters Protection against collision Simple to Operate Tool breakage monitoring Trend monitoring for wear User access controlled by RFID key | |||||

| Applications | N/A Metal forming machines Stamping | N/A | N/A Metal forming machines Stamping | N/A Metal forming machines Stamping | N/A Metal cutting machines | |||||

| In-Tool Force Monitoring Detects | N/A Broken Stripper Plates Cracked Dies Forming Defects Loose Tooling Punch Breakage Rising/Pulled Slugs Scrap Build-up Small Chips Transfer Issues Worn Tooling | N/A | N/A Broken Stripper Plates Cracked Dies Forming Defects Loose Tooling Punch Breakage Rising/Pulled Slugs Scrap Build-up Small Chips Transfer Issues Worn Tooling | N/A Broken Stripper Plates Cracked Dies Forming Defects Loose Tooling Punch Breakage Rising/Pulled Slugs Scrap Build-up Small Chips Transfer Issues Worn Tooling | N/A | |||||

|

|

||||||||||